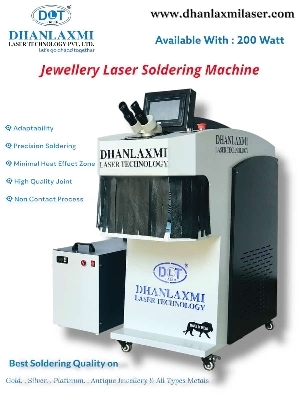

Jewelry Laser Soldering Machine

Price 360000.00 INR/ Piece

MOQ : 1 Piece

Jewelry Laser Soldering Machine Specification

- Cooling Method

- Water

- Condition

- New

- Frequency

- 50 Hertz (HZ)

- Type

- Jewelry Laser Soldering Machine

- Power

- 200 Watt (w)

- Input Current

- 230V AC single phase

- Arc Current

- 1.67 Ampere (amp)

- Weight

- 85 Kilograms (kg)

- Usage

- A jewellery laser soldering machine is a specialized tool that uses a focused laser beam to precisely weld or solder small areas of metal, commonly used in the manufacturing and repair of fine jewelry. Here's a quick breakdown:

- Voltage

- 230 Volt (v)

Jewelry Laser Soldering Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 35 Pieces Per Month

- Delivery Time

- 7 Days

- Main Export Market(s)

- Asia

About Jewelry Laser Soldering Machine

200W jewellery laser soldering machine Gold, silver, imitation jwellery , jadtar and Kundan soldering in machine Pure finishing with accuracy welding jewellery Easy weld. zero maintenance in machine.How it works: It emits a high-energy laser that melts the metal only where needed, allowing for very fine joins without damaging stones or delicate pieces nearby.

-

Main advantages:

-

Super precise and clean welds.

-

Minimal heat spread (good for work near gemstones or thin areas).

-

Faster repairs compared to traditional soldering.

-

Can work on tiny cracks, prongs, chains, rings, watches, etc.

-

-

Precise Soldering for Fine Jewelry

This laser soldering machine allows jewelers to perform highly accurate soldering tasks on small areas of metal, ensuring the integrity and beauty of delicate jewelry pieces. The focused laser beam provides exact control, reducing heat stress on surrounding components and preserving gemstones and fine details.

Efficient Water Cooling Method

The integrated water cooling system ensures that the machine operates consistently and remains protected from overheating during continuous use. This feature improves the lifespan of the equipment, delivers stable performance, and enhances safety for users, especially during prolonged jewelry manufacturing sessions.

FAQ's of Jewelry Laser Soldering Machine:

Q: How does the jewelry laser soldering machine achieve such precise results?

A: The machine uses a focused 200 Watt laser beam to target small areas with extreme accuracy, minimizing heat dispersion. This enables jewelers to weld or solder delicate components without damaging surrounding materials or gemstones.Q: What process is involved in using the water cooling method for this machine?

A: The system circulates water around key components to absorb excess heat produced during laser operation. This ensures temperature stability, protecting both the machine and the jewelry from overheating and maintaining optimal performance.Q: When is this laser soldering machine most beneficial for jewelry production?

A: It is most beneficial during tasks that require joining fine metals, repairing tiny areas, or assembling intricate designs where precision and low thermal impact are crucial to preserve the aesthetic and structural quality of jewelry.Q: Where is this jewelry laser soldering machine commonly utilized in India?

A: This equipment is widely used by professional jewelry manufacturers, exporters, and repair specialists across India, especially in production facilities and workshops focusing on fine or custom jewelry pieces.Q: What are the main advantages of using a laser soldering machine over traditional soldering tools?

A: Laser soldering offers superior precision, reduced thermal stress, faster operation, and higher quality joins. The focused laser allows intricate designs and minimizes the risk of damage to delicate materials or finished surfaces.Q: How should the machine be maintained to ensure long-term usage?

A: Regularly check and replenish the water cooling system, clean the laser lens, and ensure electrical connections are secure. Periodic professional servicing is recommended to maintain optimal output and safeguard the equipment's lifespan.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Jewellery Laser Welding Machine Category

JEWELLERY SOLDERING MACHINE WITH CCD

Price 320000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Type : Jewellery Soldering Machine with CCD

Condition : New

Frequency : 50/60 Hz

Power : 200W

GOLD SILVER JEWELLERY LASER REPARING MACHINE

Price 400000 INR / Piece

Minimum Order Quantity : 1 Piece

Type : Jewelry Laser Welding Machine

Condition : New

Frequency : 50 Hertz (HZ)

Power : 200 Watt (w)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free